We're here to help

We have a team of expert staff on hand to help - simply get in touch...

Get in touch

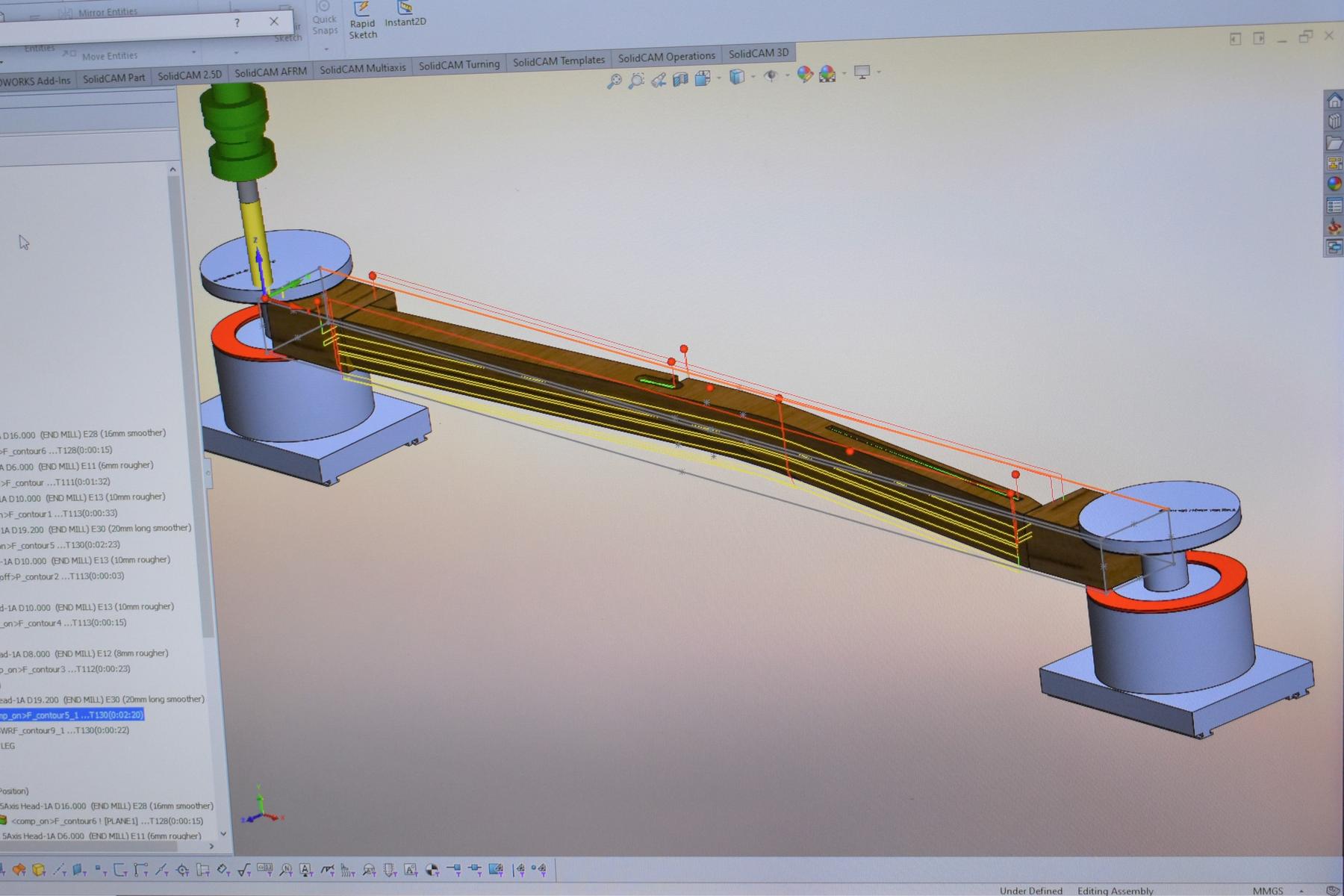

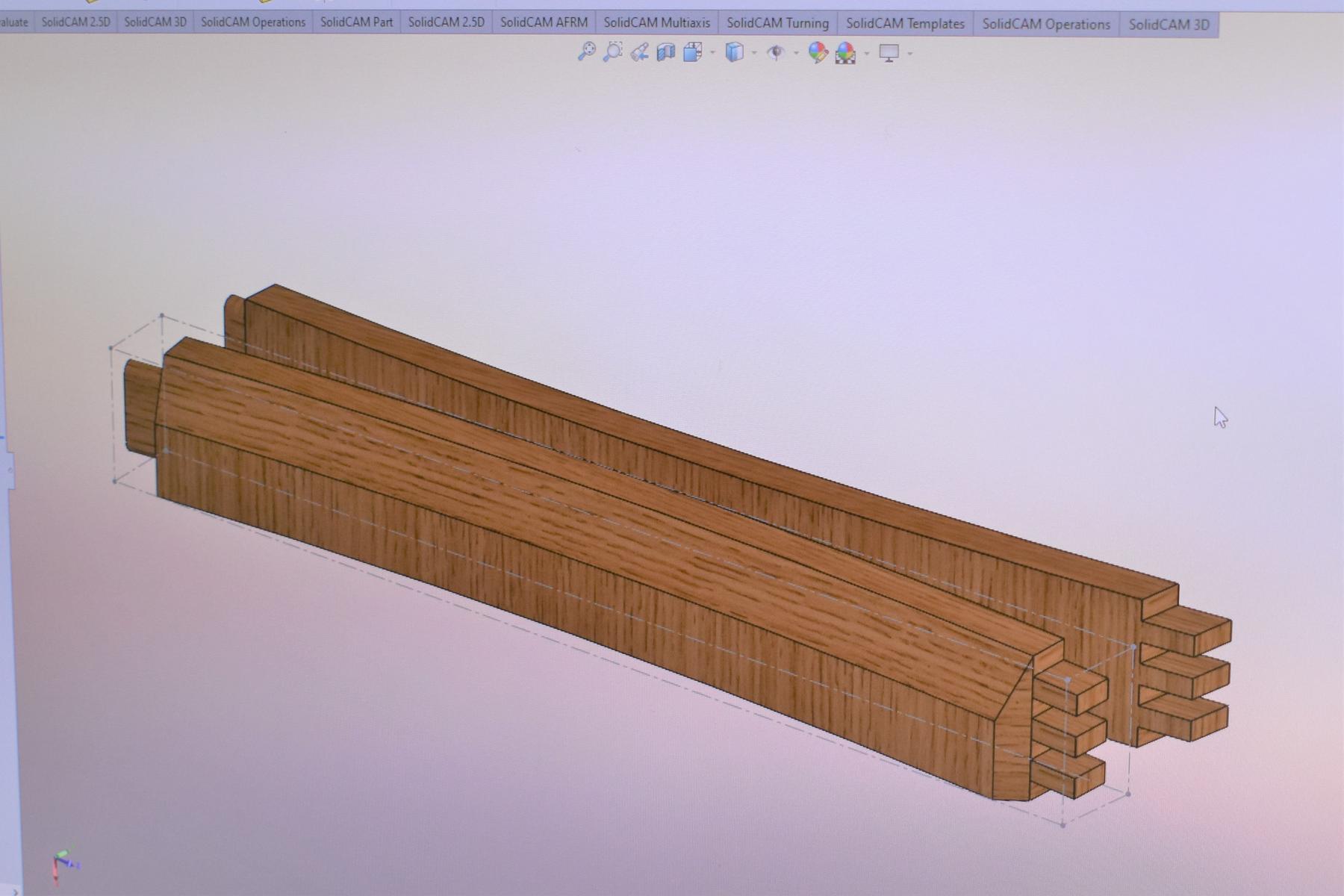

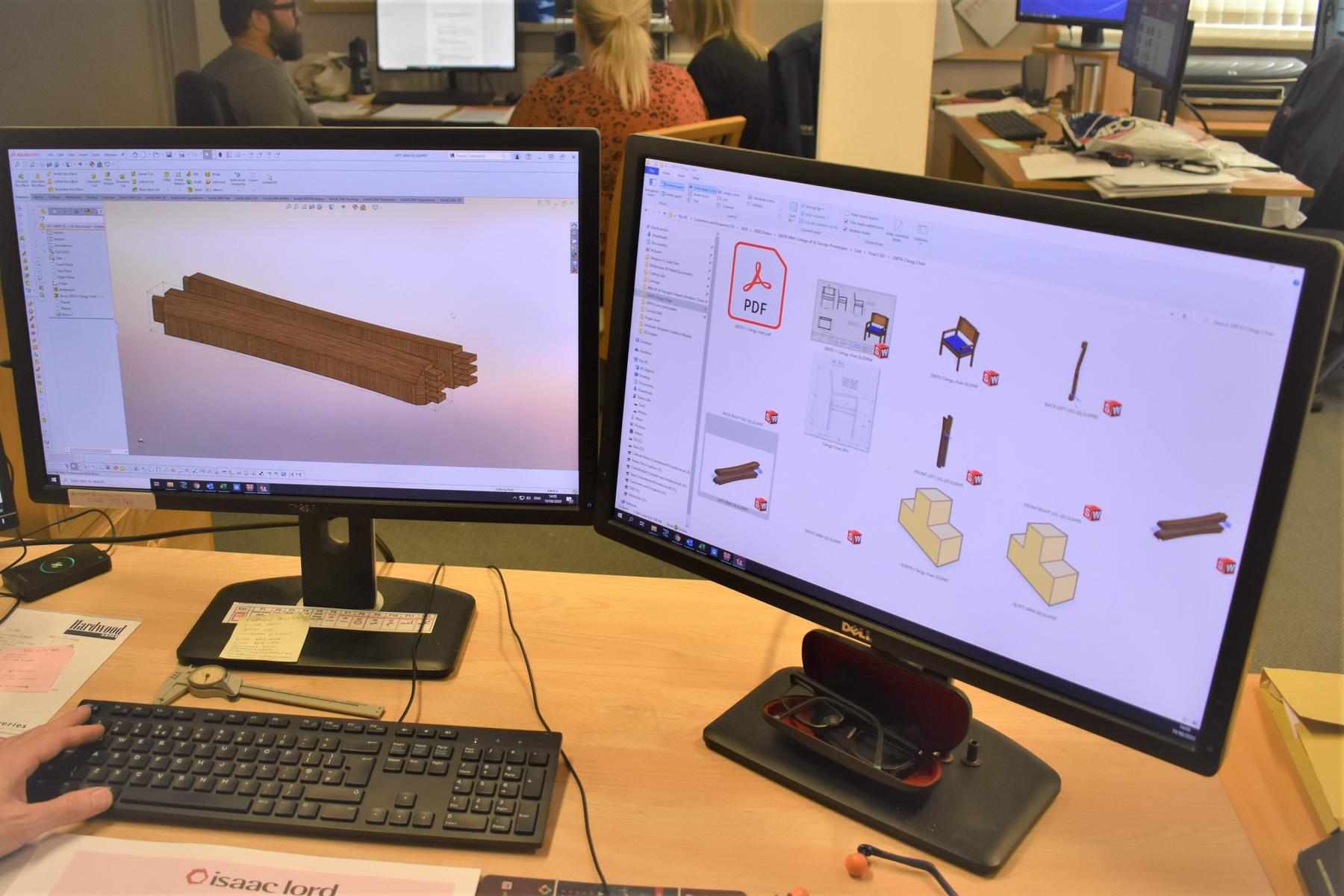

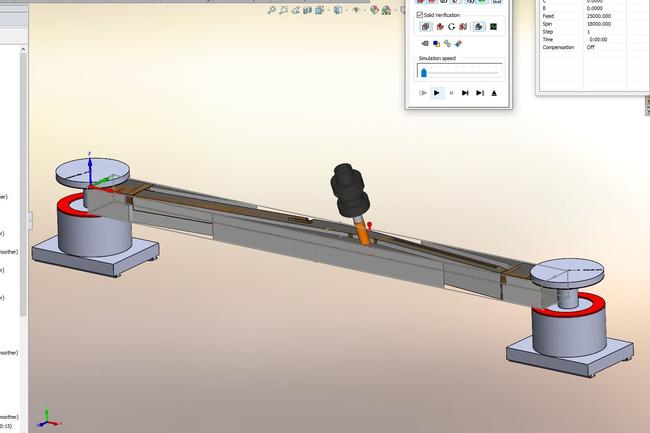

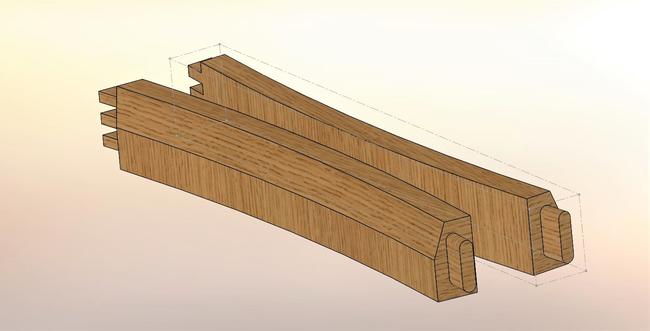

Treske are skilled and innovative wood machinists, using Solidworks and Solidcam to design and drive 3 and 5 axis CNC routing machines to efficiently manufacture bespoke furniture components for the furniture trade.

We work with trade furniture manufacturers where specialist CAD design and CNC machining skills are required to make precise prototypes, bespoke furniture components, precision wood carving and bespoke kitchen carcasses, including CNC wood cutting and 3D wood carving.

We supply CNC wooden components and other trader furniture services to support trades across the UK from our local workshop in Thirsk, near York.

Customers can supply their own design files or Treske's inhouse CAD designers can work with you to developed the design from the ground up. This can involve 3D modelling and photo realistic rendering to help judge aesthetics and can be an indespensible tool in communicating your vision to end users of the product.

Treske use both 3 Axis and 5 Axis CNC routing machines to manufacture precisions furniture components. With experience of manufacturing complex shapes with skills, that have been developed in the manufacture of our own bespoke furniture in our workshops here in Yorkshire, we are available to assist in your own trade CNC wooden component production.

We have an experienced team of CAD designers, able to work with clients to produce bespoke CNC prototypes to enable product testing and facilitate concept development. CNC furniture components can also be manufactured in a variety of materials.

Treske uses optimising software to minimise the waste from any sheet materials. Kitchen, Bedroom or Office furniture makers who require carcasses to be machined prior to assembly can take time out of their process and have parts manufactured for them to assemble.

Treske can offer a choice of edge banding from veneers to solids.

Treske can also offer assembly and finishing if required.

The gap between prototyping and mass production is often difficult to fill with the right quantity of product. Treske will quote and manufacture small order quantities, allowing customers to minimise their outlay while a product enters the market.

Individual components that require CAD/CAM expertise are made to order.

Using specialist programming and CNC 5 Axis machines Treske can carve logos and figures into solid timber components.

Treske can CNC cut many materials including solid hardwoods, plywood and laminated board, MDF, chipboard and veneered boards. Treske can also CNC model board, harder foams, sign boards, Corian and various plastics.

Treske have veneer and laminate pressing capability and can press curved and flat components..

Treske can take designs in many formats such as but not limited to .DXF, .DWG, .IGES, .SKP (SketchUp), Rhino, .STL, Solidworks, Postscript, Vectorised PDFs, we can also work from 3D files such as .3DA, .3DP, 3DS, 3D DXF, .STL, .OBJ, .DMT, IGS, & .IGE

We can also create vectorised files from photographs creating 2d or 3d objects for manufacture.

If you would like more information on any of Treske's trade services or would like a quote for a specific project, simply use our enquiry form to let us know what you're looking for and we will get back to you asap...

We have a team of expert staff on hand to help - simply get in touch...

Get in touch